MARKETS SERVED

As a custom injection molder, 3D Plastics is capable of manufacturing products for a wide range of markets and industries. Primarily 3D Plastics, manufactures for the Consumer, Dental, Medical, Electrical, and Industrial Industries. However we do not limit ourselves to a particular industry and are proud to serve you with your specific needs.

Consumer

The consumer industry is comprised of various parts and products that may go on to be sold to the individual buyer. For this reason, the design, appearance, and quality is just as important as it is for the other industries. While the product may not need the same characteristics as other industries, the attention that we pay to the product is not any less.

We mold a wide range of molding consumer products, such as firework holders, magnifying lenses, and various enclosures for today’s youth. Our staff is fully capable and will assist in any design or engineering questions.

Medical

Plastic has became a low cost alternative for products within the medical industry. While the cost may be lower, the complexity and accuracy are comparable to a more expensive method for producing the part. The medical industry, much like the dental industry, is comprised of many thermoplastic and silicone products. Common medical products consist of gaskets, DNA holders, and various housings for medical components.

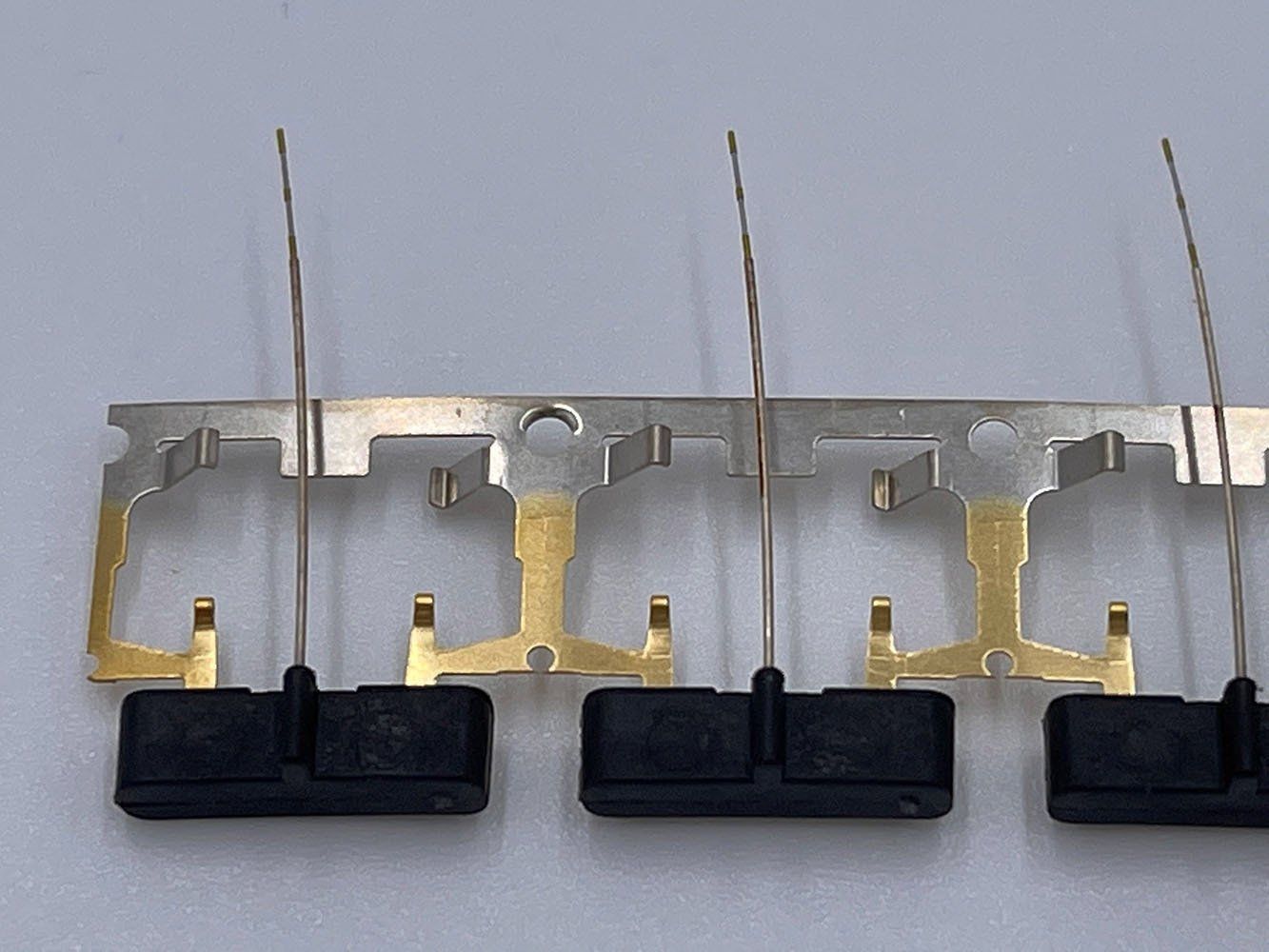

Electrical

We have extensive experience molding plastic products that are used within the electrical market. Many products within this market, demand very tight tolerances and specific dimensions, used in electrical components. The products range from housings to electronic packaging to various components. These products are often characterized by very complex designs. 3D Plastics works with designers and engineers to help certify that the customer’s product is taken from concept to final design.

Industrial

Industrial markets demand stiff products that will not be susceptible to bending under extreme pressure or heat. Collaborating with designers and engineers, our staff can make sure your product can stand up to these demanding characteristics and give you the desired performance.

Various materials also help add structure to an industrial product, that may help retain the rigidness of your product under extreme factors. Our staff is glad to assist you in determining what material may be most suitable for your particular project. We can produce parts for your industrial project ranging from a few ounces to 2 pounds.